Grandes estruturas para montagens de Caldeiras aquatubular-Planta completa.

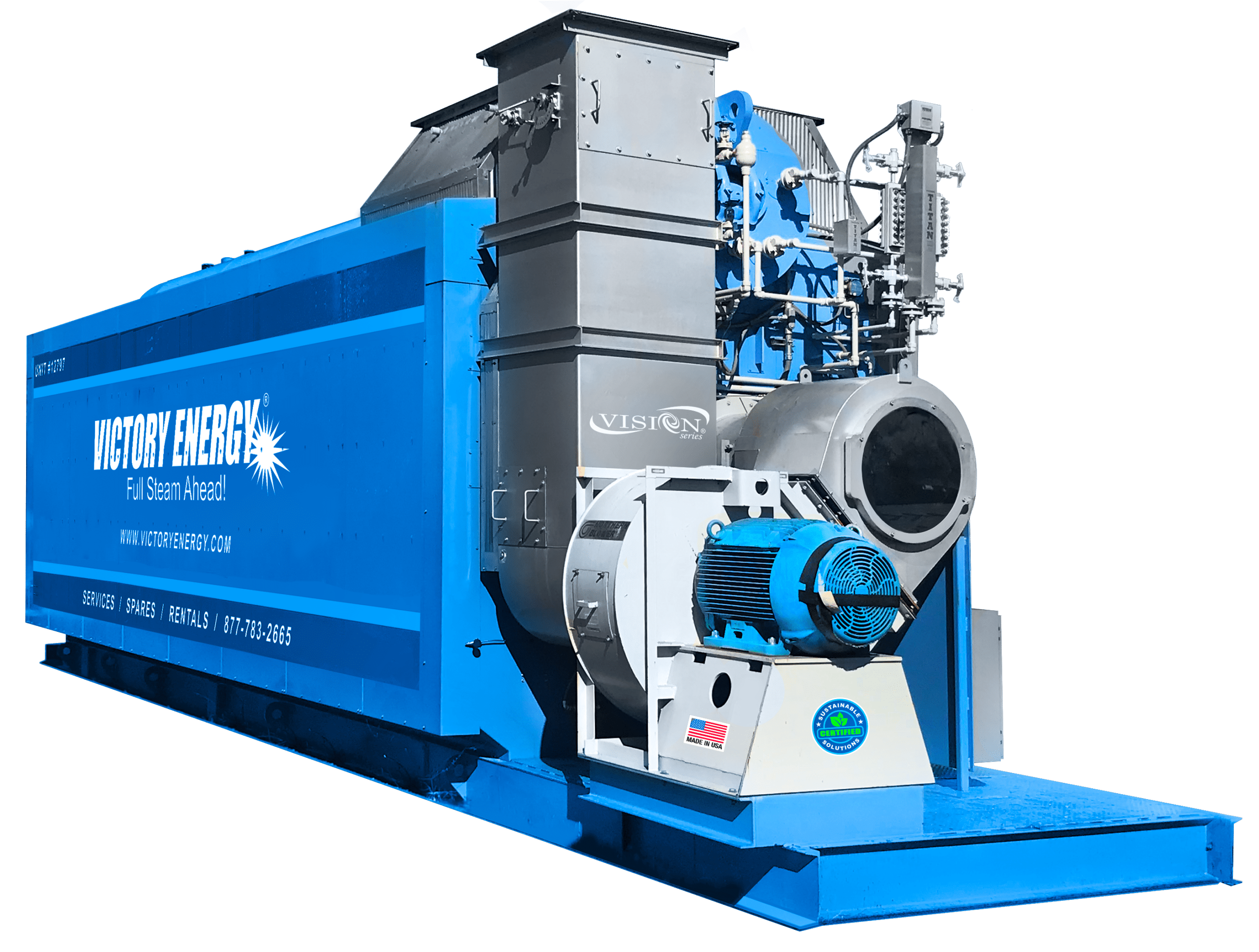

Powerhouse Mechanical & Combustion Corporation proudly offers all Victory Energy Watertube Boilers.

Victory Energy manufactures a full line of industrial watertube boilers. Suited for all industrial and institutional applications. We have hundreds of watertube boilers in operation worldwide bringing the latest innovations that deliver the most efficient steam boilers on the market.

No application is too small or too large. We thrive in an atmosphere of innovative thinking and breakthrough methodology. We carry this attitude forward from “Concept to Completion” as we work closely with our customers, in-house engineering teams, in-house project management teams, fabrication personnel, manufacturing crews, logistics department and field technicians.

In addition to providing rock-solid solutions that are reliable and compliant with the most stringent technical requirements, we are constantly looking for ways to maximize the efficiencies and value of total integration for our customers and end users.

Quality materials and superior construction are essential to producing industrial-duty boiler systems that are, by design, engineered to be the most reliable boilers in the world. Our approach to modularization is designed to maximize shop assembly while minimizing costly field labor and delivery time.

From permanent full-scale installations to temporary mobile systems, Victory Energy offers custom-engineered solutions for all types of applications in all kinds of industries including Petroleum, Utility/Power, Textiles/Pulp & Paper, Chemical Processing, Process Waste Heat, Institutional, District Heating, Ethanol, Oil Sands/Enhanced Oil Recovery and Thermal Solar projects.

O-TYPE WATERTUBE

The Victory Energy VOYAGER® O-type industrial watertube boiler is designed to provide a rapid ramp rate and is easy to ship, install, operate and maintain. These versatile, robust boilers have become very popular for applications that are extremely demanding in harsh environments.

Its symmetrical configuration is ideally suited for restrictive floor plans, while the gas outlet allows the addition of an enhanced heat recovery system in a vertical configuration to maintain the most efficient overall footprint.

Steam capacities rage from 10,000 PPH up to 500,000 PPH, design pressures from 250 PSIG to 2,000 PSIG with saturated and superheat temperatures up to 1,050 degrees F. Superheated versions are designed to minimize the steam temperature fluctuations across the operating range of the boiler.

Each VOYAGER O-type industrial watertube boiler is custom engineered with constructability in mind.

CAPACITIES

- Up to 500,000+ PPH

- Pressures range up to 2,000 PSIG

- Temperatures up to 1,050˚F

- Saturated or superheated steam

- Ideal for restrictive floor plans

D-TYPE WATERTUBE

Victory Energy’s DISCOVERY® D-type industrial watertube boilers are operating in hundreds of industrial applications in a multitude of industries worldwide. This proven design offers large furnaces and are engineered for long-term reliability and are well suited for high-pressure superheated steam applications with restrictive heights.

Units range well in excess of 500,000 PPH. Modular and field-erected sizes are available as well as customized solutions including elevated/remote steam drum configurations. Convective style superheaters are desired when fuels are heavily laden with ash and superheat is required. All superheaters are placed within the boiler’s convective zone to eliminating exposure to the radiant energy in the furnace and ensures a long and reliable operating life. This conservative approach reduces harmful emissions.

CAPACITIES

- Up to 500,000+ PPH

- Pressures range up to 2,000 PSIG

- Temperatures up to 1,050˚F

- Saturated or Superheated steam

- Ideal for large capacities and modular configurations

A-TYPE WATERTUBE

Victory Energy VOYAGER® A-type industrial watertube boilers are designed to provide a rapid ramp rate and are easy to ship, install, operate and maintain. These versatile, robust boilers have become very popular for applications that are extremely demanding in harsh environments.

Its symmetrical configuration is ideally suited for restrictive floor plans, while the gas outlet allows the addition of an enhanced heat recovery system in a vertical configuration to maintain the most efficient overall footprint.

Superheated versions are designed to minimize the steam temperature fluctuations across the operating range of the boiler.

CAPACITIES

- Up to 500,000+ PPH

- Pressures range up to 2,000 PSIG

- Temperatures up to 1,050˚F

- Saturated or superheated steam

WHB WATERTUBE

Victory Energy offers a wide variety of HORIZON® Series watertube boiler solutions for a multitude of heat recovery applications, whether the need is hot water, steam (saturated or superheated) or high temperature thermal fluid.

No matter if the flue gas is clean or contains ash, whether its derived from a process in which the heat would otherwise be wasted or it comes from a purpose built combustion or gasification system that requires steam to generate power, Victory Energy has the solution.

Victory Energy’s proprietary modeling tools allow for the optimal finned tube design for the production of boilers to fit into small footprints which helps greatly reduce radiant heat losses, all without the compromising reliability

CAPACITIES

- Up to 500,000+ PPH

- Pressures range up to 2,000 PSIG

- Temperatures up to 1,200˚F

- Custom Engineered and Modularized

Comentários